Your customers are more demanding than ever before. Improving field quality and your customer's experience of your product is essential to staying competitive. However, truly understanding customer experience can be a daunting task. These recommendations have been refined and proven in dozens of manufacturers as simple ways to rapidly improve field quality performance.

1. Think big; start small.

1. Think big; start small.

The volume of product, process, and customer data that is being collected today is unprecedented. Data have gotten so big that term "Big Data" is going out of style. Warranty & service contract claims, call center records, telematics & sensor data, social media posts, sales records, product information, Bill of Materials, and many other sources contain valuable insights. But each only tells part of the story. Integrating these sources provides a holistic view of field quality. Unfortunately, in most organizations each data source exists in its own silo. To drive value quickly, it is important to think big, but start small.

Think big by creating a comprehensive data plan. Understand what data are available that could expand your understanding of customer experience and product performance. Gather a cross-functional team and brainstorm. Don't stop at the obvious or the easy data. This big picture plan will become your roadmap.

The big picture is important, but it's easy to get overwhelmed. That's why you need to start small. Break the plan into phases. Start by focusing on a few key data sources that will drive the most value. For most manufacturers, warranty claims are the most comprehensive, detailed information available for assessing field quality. However, claims aren’t enough. A few essentials need to be added to claim data to make it useful for anything beyond paying the service center. Sales information allows you to look at rates instead of counts. Product information lets you compare across assembly locations, build combinations and time. These data sources make up the core of a field quality analysis system.

2. Detect issues sooner.

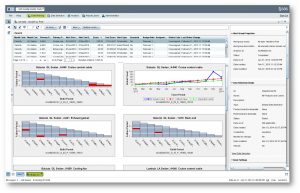

You don't have time to stumble across new quality issues or chase after false alarms. The longer it takes to find an issue, the longer it takes to resolve it. That means more defective products make it out the doors of your assembly plant. Automated analytics focus your problem solvers on the right issues and allow them to start the problem-solving process months earlier.

Analytics are critical, but not all "analytics" are created equal. Dashboards, trends, and point-to-point comparisons are not sufficient. Effective early warning analytics must:

- Set critical values based on historical patterns, not manual thresholds

- Monitor changes over build period, time in service, and event period simultaneously

- Filter out the noise of normal variation

- Account for seasonal patterns

- Tolerate the idiosyncrasies of field quality data

Automation is also critical. There are hundreds of thousands of combinations of things that can go wrong. And new data are being added constantly. Its not practical to expect analysts and engineers to dig through all of those data to find emerging field quality issues. The reality is that emerging issues will slip through the cracks for months or even years until they make their way to a top issue list. By then huge volumes of defective products will have entered the market. Automating the analytic process provides engineers and analysts with actionable insights that can be used to start the problem solving process.

3. Accelerate problem resolution.

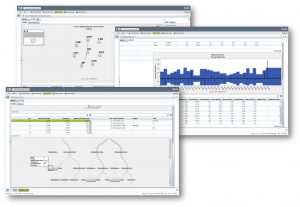

Whether an issue is detected through an automated, analytic early warning system or through a phone call from an irate executive, the next step is the same. Define exactly where, when and under what conditions the failures are occurring. The faster you can move from detection to correction, the more money you save.

However, determining exactly where, when, and in what combinations parts are failing is often a long and arduous process. Analytics can improve your speed, accuracy, and precision beyond basic slicing and dicing. This allows you to efficiently focus your scarce resources and understand the true casual factors.

Unfortunately, trends, Paretos, and other standard ways of visualizing data are not sufficient. They can show you what the data look like, but they can't tell you whether it's normal variation, a significant pattern, or a wild goose chase.

However, analyses such as Decision Trees, Sequence Analysis, Analysis of Means work well with field quality data and quickly isolate significant potential causal factors. This allows you to narrow your focus and get to the true root cause of the problem more quickly.

4. Communicate goals and progress.

Most manufacturers agree that reducing quality costs and improving customer satisfaction are strategic objectives. However, very few organizations communicate the necessary information needed for their people to align their personal goals to these strategic objectives.

To work together, team members need to know:

- What are the key metrics? When it comes to field quality, there is no shortage of things that are measured. The secret is to identify your organizations strategic objectives and focus on the metrics that most clearly measure those objectives. If a metric isn't tied in one way or another to those strategic objectives, why track it?

- How are we doing? Now that your people know what to focus on, they need to understand the goals and current performance. Communicating this information in a hierarchical format helps them understand how individual business units, model lines and suppliers are doing and how they influence overall performance.

5. Learn from others.

There is no need to reinvent the wheel. Benchmarking your peers in other industries can quickly give you an advantage over your competitors. Dozens of manufacturers around the world have implemented the recommendations outlined above. The following case studies provide examples of putting these ideas into action:

- Freezing out the issues: Sub-Zero halves warranty claims by employing analytics

- Provide service, maintenance before a breakdown: Volvo’s QRAFT analytical solution anticipates its customers’ needs

- Lenovo Shines an LED on Customers' Perception of Quality

Manufacturers have proven that following these best practices takes months out of the problem-solving process, reduces warranty costs, and improves customer satisfaction. Each step along the journey is valuable. The key is to stay focused and learn from the success of others.

I'd love to hear from you. What's your experience with these methods? What did I leave out? Add your suggestions in the comment section below.